-

أهمية مكونات جهاز كشف المعادن في فحص الأمان والحماية

مكونات جهاز كشف المعادن تعتبر عنصراً أساسياً في فحص الأمان والحماية، حيث تساهم هذه المكونات في تحديد وكشف أية مواد معدنية قد تشكل تهديداً على سلامة الأفراد…

-

كيفية صنع جهاز كشف المعادن بطريقة بسيطة وفعالة

كيفية صنع جهاز كشف المعادن يعتبر جهاز الكشف عن المعادن من الأدوات الضرورية والمفيدة في عدة مجالات مثل الهوايات والتنقيب عن الآثار وحتى في الأمن والسلامة….

-

كيفية صنع جهاز كشف الذهب: خطوات بسيطة لصنع جهاز كشف الذهب في المنزل

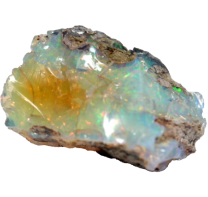

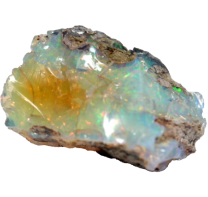

كيفية صنع جهاز كشف الذهب في بداية المقدمة تعتبر أجهزة كشف الذهب من الأدوات الهامة للكشف عن وجود الذهب والمعادن الثمينة في الأرض. وفي هذا السياق، يمكن للأش…

-

كيفية صناعة جهاز كشف المعادن بطريقة فعالة

كيفية صناعة جهاز كشف المعادن في بداية المقدمة، يعتبر صناعة جهاز كشف المعادن من أهم العمليات التي تتطلب دراسة واستكشاف لتحديد الطرق الفعالة لتصميم وتصنيع جه…

-

كيفية صناعة جهاز كشف الذهب: دليل شامل للمبتدئين والمحترفين

كيفية صناعة جهاز كشف الذهب: دليل شامل للمبتدئين والمحترفين إذا كنت تبحث عن الطرق الفعالة لصناعة جهاز كشف الذهب، فأنت في المكان المناسب. يعتبر جهاز كشف الذ…

-

كيفية كشف الذهب تحت الأرض بفعالية ونجاح

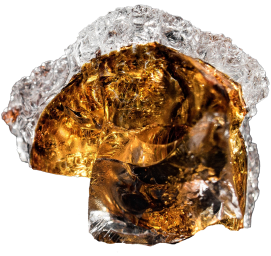

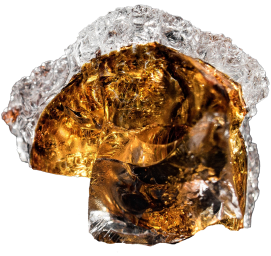

كشف الذهب تحت الأرض هو عملية مهمة ومثيرة تستخدم فيها العديد من التقنيات والأدوات للعثور على الذهب المدفون في باطن الأرض. يعتبر الذهب من أثمن المعادن وأكثره…

-

كيفية تصميم وفكرة عمل جهاز كشف المعادن

فكرة عمل جهاز كشف المعادن إنّ تصميم جهاز كشف المعادن هو عملية معقدة تستند إلى فكرة عمل دقيقة تعتمد على الاستشعار والتحليل للتعرف على العناصر المعدنية الموج…

-

كيفية عمل جهاز كشف الذهب: دليل الخطوات السهلة والفعّالة

طريقة عمل جهاز كشف الذهب: دليل الخطوات السهلة والفعّالة يعتبر جهاز كشف الذهب أحد الأدوات الحديثة التي ساهمت في تسهيل وتسريع عملية البحث عن الذهب والمعادن…

-

طريقة استخدام جهاز كشف الذهب بشكل فعال وسهل

طريقة استخدام جهاز كشف الذهب هي عملية أساسية للباحثين عن الكنوز والثروات الطبيعية. فالجهاز الذي يمكنه كشف الذهب والمعادن الثمينة يعتبر أداة حيوية لعشاق الب…

-

سعر جهاز qz80: كيف تحصل على أفضل عرض لهذا الجهاز المثير؟

سعر جهاز qz80: كيف تحصل على أفضل عرض لهذا الجهاز المثير؟ إذا كنت تبحث عن جهاز qz80 وترغب في الحصول على أفضل سعر لهذا الجهاز المثير، فأنت في المكان الصحيح….

Search

About

Lorem Ipsum has been the industrys standard dummy text ever since the 1500s, when an unknown prmontserrat took a galley of type and scrambled it to make a type specimen book.

Lorem Ipsum has been the industrys standard dummy text ever since the 1500s, when an unknown prmontserrat took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

Archive

Categories

Recent Posts

Tags

أجهزة كشف الذهب والكنوز احدث اجهزة كشف الذهب والكنوز الدفينة احدث جهاز كشف المعادن ارخص جهاز كشف المعادن افضل جهاز كشف المعادن افضل جهاز لكشف المعادن جهاز teknetics t2 جهاز استكشاف المعادن جهاز اكتشاف المعادن جهاز المعادن جهاز جاريت ابيكس جهاز جولد ستينجر جهاز كشف الفراغات تحت الأرض جهاز كشف المعادن والاثار جهاز كشف معادن يدوي

Gallery